VCP-J Pipe Details & Dimensions

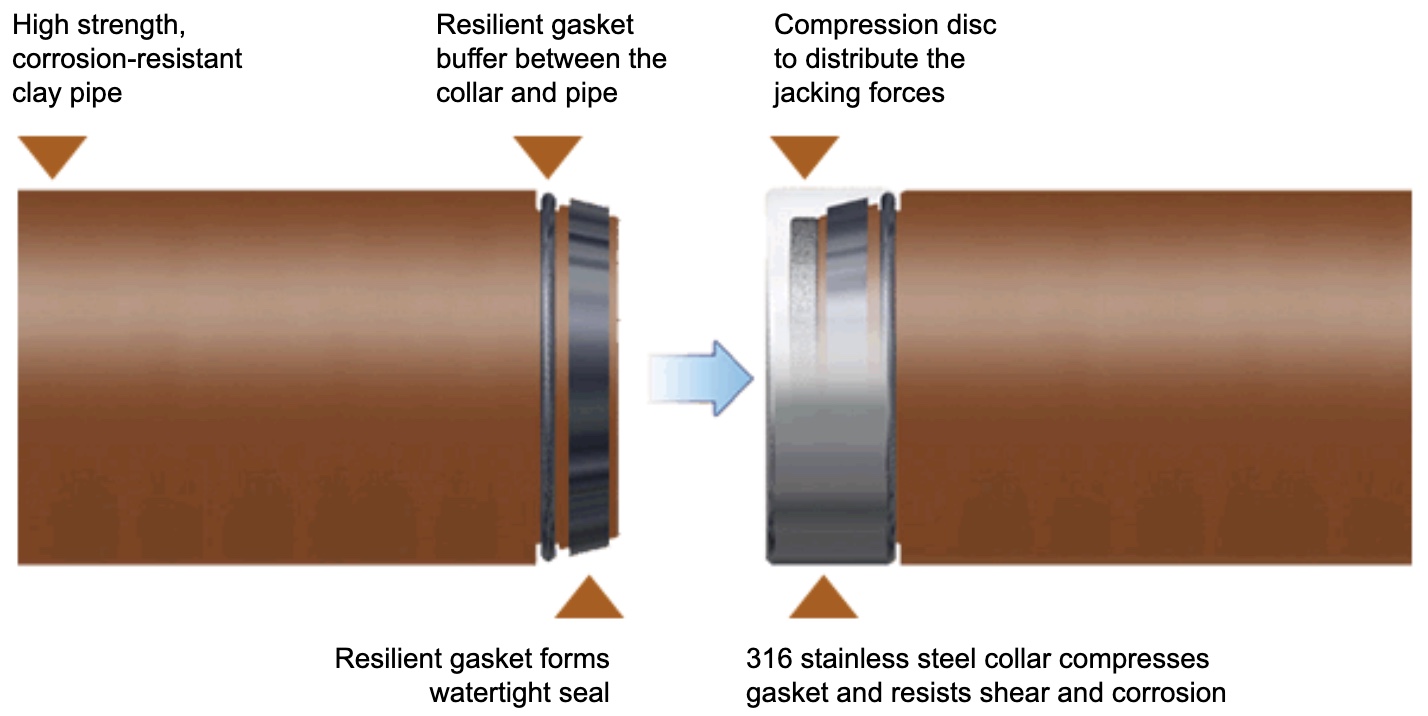

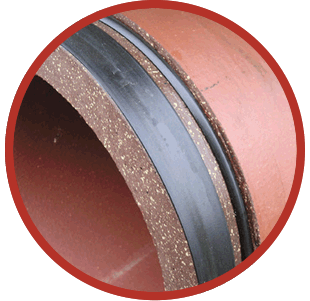

Precision-machined squared ends

| NO-DIG Pipe Specification | |||||

| Nominal I.D. | Average O.D. |

Approx. Pipe Weight lbs. per ft. |

Allowable Safe Jacking Load (in Tons) | ||

| 2.5 SF* | 3.0 SF* | 3.5 SF* | |||

| 8" | 11" | 41 | 41 | 34 | 29 |

| 10" | 135/16" | 60 | 60 | 50 | 43 |

| 12" | 151/2" | 78 | 78 | 65 | 55 |

| 15" | 187/8" | 106 | 109 | 91 | 78 |

| 18" | 22 | 133 | 141 | 117 | 100 |

| 21" | 251/2" | 178 | 189 | 158 | 135 |

| 24" | 291/8" | 229 | 230 | 192 | 165 |

* SF = Safety Factor – SF numbers are based on 7000 psi compressive strength (The minimum requirement of ASTM C1208). NO-DIG Pipe consistently exceeds the minimum requirement.

Maintenance considerations for NO-DIG pipe are consistent with all vitrified clay pipe installations. For more information, see the Vitrified Clay Pipe Engineering Manual from the National Clay Pipe Institute.

- Use with the Pilot Tube Method of Guided Boring for on-target line and grade

- Unsurpassed axial strengths

- 316 stainless steel collars

- Available in 1- and 2- meter standard lengths

- Chemically resistant

- Works below the water table

- Exceeds the standard for ASTM C1208 Standard Specification for Vitrified Clay Pipe and Joints for Use in Microtunneling, Sliplining, Pipe Bursting, and Tunnels

- Highly sustainable – doesn’t degrade over time

- May reduce the need for lift stations